Chemistry Pole

CHEMISTRY CENTER

The Petrochemicals, Plastics and Rubber sector is rooted in Rio Grande do Sul and stands out for its constant innovation in the development and improvement of products. In Brazil, the sector developed from the middle of the last century, when the internal demand for plastic grew, and in four segments:

· The base industry, responsible for the production of basic petrochemicals, considered first generation – ethylene, propylene, butadiene, benzene and styrene. Its main inputs are naphtha and natural gas.

· Following the chain, the manufacturing industry of petrochemical resins, products of the second generation of the chain, such as polyethylene, polypropylene, polystyrene and elastomers (rubber)

· The next segment in the chain, the 3rd generation, includes companies that transform these raw materials into plastic material and rubber products. While the petrochemical industry produces the raw materials for the rest of the production chain, the transformation of plastic and rubber is characterized by its multitude of uses and for being part of the value chain of a large number of productive sectors.

· At the end of the chain is the recycling of plastic products. This segment grows in the country and in the state.

More recently, innovations in the chemical industry allowed the development of green plastics, produced from vegetables, sugar cane, corn, beets and others, generating ethanol (1st generation) or biodegradable thermoplastic resins (2nd generation).

In Brazil, there are four main petrochemical poles, which integrate first and second generation plants. One of them is located in Rio Grande do Sul. The Triunfo Petrochemical Complex, opened in 1982, has a production capacity of 1.4 million tons/year. It has three innovation centers that stand out in Latin America. The first, Innovation & Technology Center, comprises 14 laboratories and 7 pilot plants (Braskem). This center, among other innovations, enabled the development of the first green polyethylene plant produced from sugarcane in the world. The Styrenic Technology Center (CTE) integrates four resin innovation and improvement laboratories (Innova). And the third research center, Polo Films, is made up of a laboratory for physical and chemical tests focused on quality, new applications and development of bioriented polypropylene films (CofipRS).

Rio Grande do Sul, in the petrochemical, plastics and rubber sector, is a leader in innovation and has one of the largest industrial parks in the country. To this end, the sector can count on increasingly prepared researchers and professionals, trained by the network of universities, institutes and technical schools present in the state. In the municipality of São Leopoldo, the presence of the Polymer Transformation Center (Cetepo) stands out, which develops applied research and innovation projects and provides metrological services and technological consultancy for the sector.

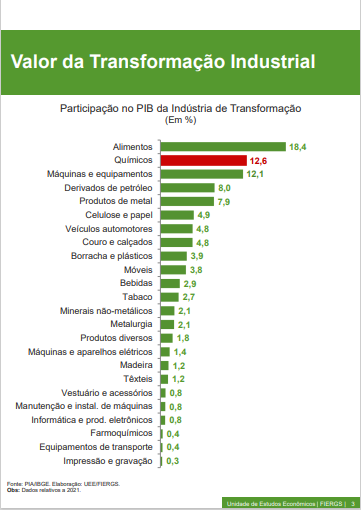

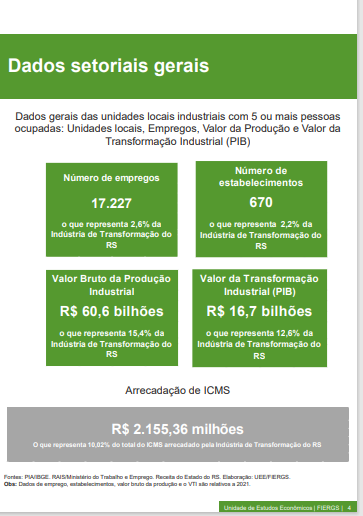

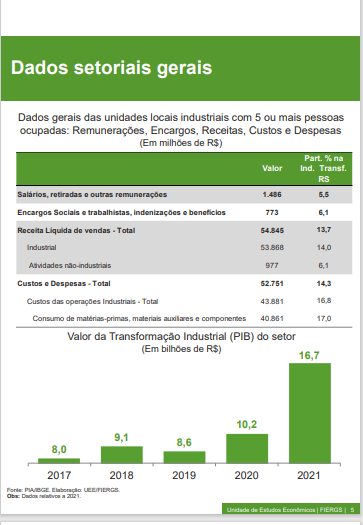

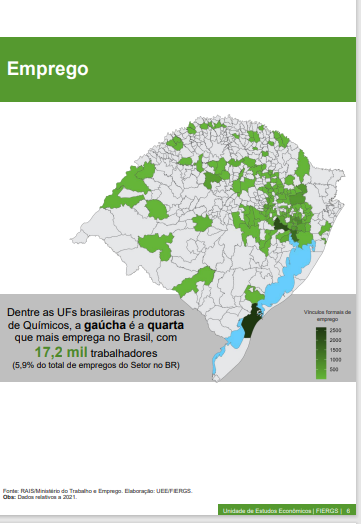

The rubber and plastic materials sector (3rd generation) employed 415,025 workers in Brazil in 2020, 37,268 of which in Rio Grande do Sul. In this segment, the state is 2nd in the ranking of number of companies (1,390), accounting for 10% of Brazilian establishments producing rubber and plastic materials (MTE). The sector accounts for 2.2% of the added value of the Brazilian transformation industry and for 2.7% of the transformation industry of Rio Grande do Sul (CNI).

Brazil has 2% of the world production of thermoplastic resins, occupying the 8th position in the world ranking. Rio Grande do Sul occupies the 2nd place in the ranking of producers among Brazilian states.

The plastic transformation sector in Brazil is made up of 11,032 companies with revenues of R$ 127.5 billion. In this scenario, Rio Grande do Sul concentrates 1.2 thousand companies, occupying the 2nd position in the country and employing 28,587 people. The state's participation in this sector is 10.7%. With 258 companies, the municipality of Caxias do Sul is the 2nd Brazilian municipality with the highest number of companies (Abiplast). Still on this sector, companies in the state are medium and small and offer a variety of products: components for the automotive, furniture, civil construction, refrigeration, and footwear industries, among others; packaging; recycled; household items; thermal and acoustic insulation materials; between others.

According to the Union of Plastic Material Industries of Vale dos Vinhedos (Simplavi), the main market for products manufactured by companies linked to the sector is the domestic market, which is already consolidated.

With regard to machinery, equipment and the matrix and mold industry for plastics, the state, along with São Paulo and Santa Catarina, has the highest concentration of companies, with emphasis on the municipality of Caxias do Sul (Sebrae).

The manufacturing segment of rubber products employs, in Brazil, 87.4 thousand people, with Rio Grande do Sul contributing with 8.87% or 7.7 thousand jobs, ranking 2nd among the Federation Units.

The rubber sector in Rio Grande do Sul is quite diversified, with products serving the industry and the retail market. It supplies several production chains, especially the automotive sector. In Rio Grande do Sul, there are large industries producing tires, parts for the sectors of agricultural machinery and equipment and motor vehicles, profiles and rubber parts for different segments of industry.

The recycled segment, which generates 4th generation products, is responsible for employing 13.2 thousand people, distributed in 1.2 thousand companies, mostly concentrated in the Southeast and South regions of the country. Rio Grande do Sul, 4th among the Brazilian states, has 101 recycling companies, which employ 864 people, representing a 9% share. In 2020, 884.4 thousand tons of plastic waste were recycled in the country. It is estimated that for each ton of plastic material recycled in a month, 3.16 jobs are created for collectors and separators, 1.1 ton less plastic waste destined for urban landfills, a reduction of 1.53 tons of greenhouse gases and 75% energy savings (Abiplast).

The Chemistry Complex is a partnership between the Government of the State of Rio Grande do Sul, the Municipalities of Montenegro and Triunfo, the Chemical Industries Union of RS (Sindiquim), the Petrochemical Complex Development Committee (Cofip RS) and Braskem.

With a strategic location, close to the Petrochemical Complex, in an area of 700 hectares located in the municipality of Montenegro, it provides an environment of synergy with the entire link in the production chain. The Complex of the Chemistry Complex offers complete infrastructure, services, supply of inputs and qualified labor.

The Chemistry Complex has a logistical differential because it is surrounded by State and Federal Highways and is also served by the rail network and terminal on the internal waterway of Rio Grande do Sul. One of the competitive advantages is the Santa Clara Terminal, intended for inland navigation of container barges, connecting the Chemistry Complex to the Port of Rio Grande and global markets. The wide road network guarantees an agile flow of production, with connections to all regions of the country, Argentina and Uruguay. An extensive network serves the Chemistry Hub: BRs 116, 386 and 470 and RSs 124, 240 and 287.

The site is also served by the following railway branches:

EF-116 South Main Trunk – Center of the Country

Uruguaiana branch – West-border of RS.

With skilled labor, the Chemistry Hub has a modern training center measuring 992 m2.

The Integrated Chemistry Hub was conceived with concern and bases on the sustainable development of companies. Over 40 years, the micro-region, through State and Municipal Environmental legislation, has preserved the surroundings from the impact of urbanization. In addition, it has an Integrated Liquid Effluent Treatment System (Sitel) capable of serving new companies. These are services that include treatment, monitoring and disposal of industrial and sanitary liquid effluents from the Southern Petrochemical Complex, treatment of raw water collected from the Caí River and supply of treated water to the industrial districts of Triunfo, Montenegro and the community surrounding the Petrochemical Complex. southern.

Among the incentives that the State of Rio Grande do Sul offers for companies to establish themselves in the Chemistry Complex, the following stand out:

- Discount of 90% of the lots,

- FUDOMEPM and Integrar RS tax incentives

As well as tax incentives from the Municipalities of Montenegro and Triunfo.

Different technical studies were carried out on the main Chemical Industries with technical and economic viability for the Chemistry Pole. Reports used as a reference in data collection such as: BNDES Study on Chemical Industry diversification - Foreign Trade Statistics Report – ABIQUIM - NCM's Foreign Trade Report – ABIQUIM - NCM's data survey with associates – SINDIQUIM.

As an investment opportunity, such technical studies pointed out the following areas of the Chemical Industry with potential to be explored:

- Paints and solvents focusing on the mechanical metal sector with repressed demand. The import of rutile-type pigment was US$ 284 million in 2020;

- Cosmetics as Brazil is the 4th largest consumer country, the State is an exporter of glycerol and essential oils,

- Sanitizers, cleaning products, detergents

- Laboratory reagents in 2020 were imported by Brazil US$ 555 million in diagnostic or laboratory reagents - Supplies for

- Agricultural pesticides in 2020 were imported by Brazil US$ 5 billion in inputs for pesticides * sector growth in Brazil was 6% in 2020 with more than 38 million tons sold